Hard Alloy Sand Breaking Strips for Broken stone

- Home

- >

- Products

- >

- Carbide Sand Breaking Strips

- >

- Hard Alloy Sand Breaking Strips for Broken stone

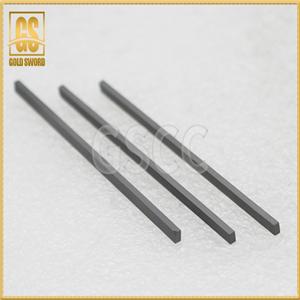

Hard Alloy Sand Breaking Strips for Broken stone

Brand :Gold Sword

Product origin :Zhuzhou, China

Delivery time :15 days

Supply capacity :10000kgs

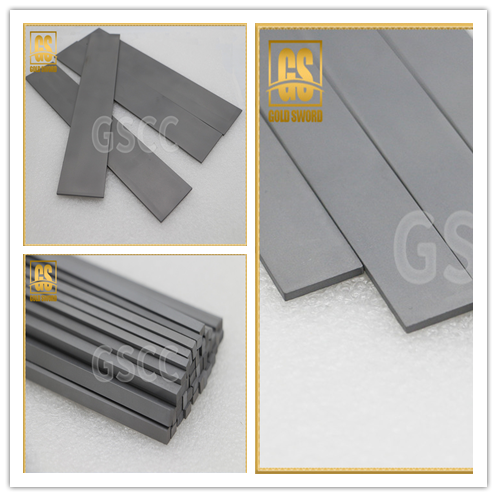

Hard Alloy Sand Breaking Strips for Broken stone is Tungsten Carbide High Wear Resistant STB Bars have

high hard ness, wear-resistance, and resistance to bending,for cutting general wood or hard wood ,used for processing blades, wear resistance parts etc.

Hard Alloy Carbide Sand Breaking Strips has high hardness and high wear resistance, it is a ideal choice to used in Broken stone

With high quality raw material and advanced equipment, G.S.carbide provides customer superior quality Hard Alloy Sand Breaking Strips for Broken stone

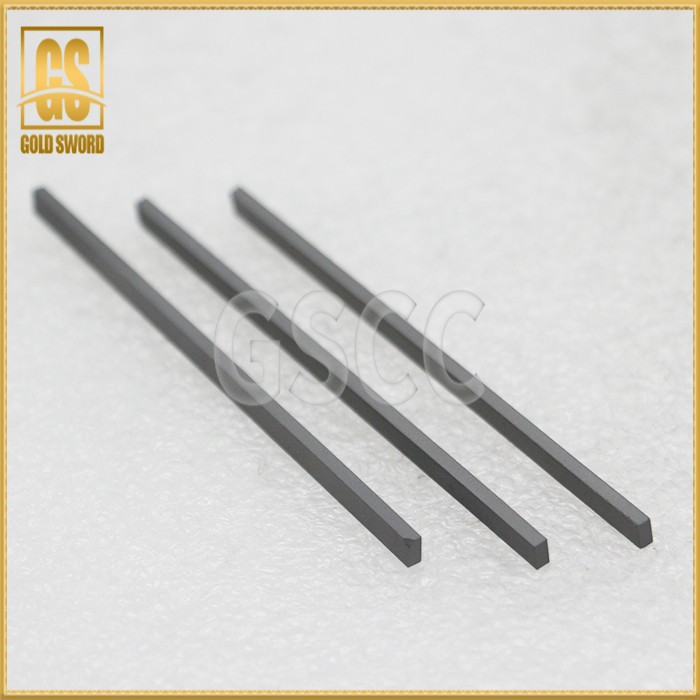

1.Easy to be brazed, good wear resistance and toughness.

2.Untrafine grain size raw material to keep excellent strength and hardness.

3.Both standard sizes and customizes sizes are available.

Tungsten Cemented Carbide Strip for Broken stone

Advantage:

1. We Over 10 Years' efforts in making high quality Hard Alloy Sand Breaking Strips for Broken stoneard , Almost 8 years in doing importing and exporting business.

2. Rich experience in grade researching, mould designing, automatic press, HIP sintered, surface treating and quality control.

3. We have many years of experience in producing the tungsten carbide strips and have gained a wide reputation in the market . Welcome your inquiry anytime .

About Hard Alloy Sand Breaking Strips for Broken stone :

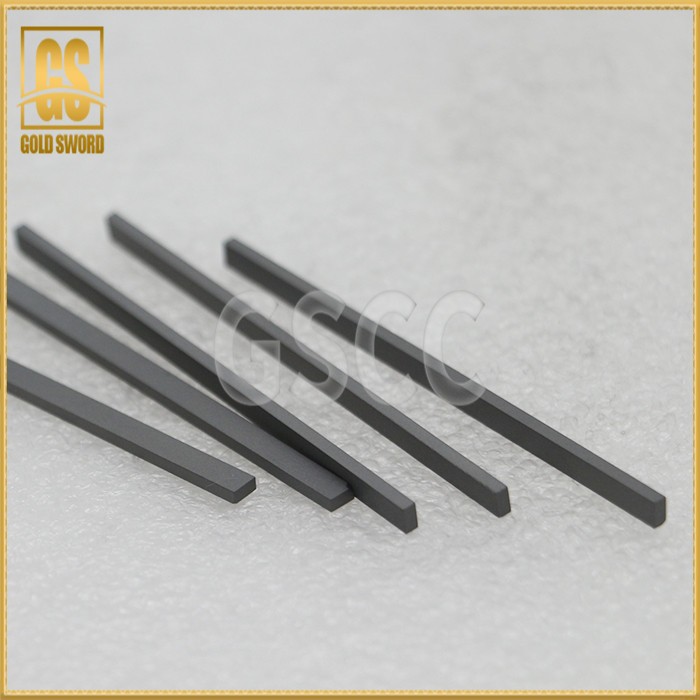

The main composition of Hard Alloy Sand Breaking Strips for Broken stone is tungsten carbide powders and cobalt powders .With its wear resistant and corrosion resistant ability , tungsten carbide nowadays is widely used in many areas such as : cutting tools , moulds , oil and automobile industry etc .

Tungsten carbide strip and Hard Alloy Sand Breaking Strips is used as the cutter for the TCT woodworking knives for cutting all kinds of original wood , hard wood , HDF, MDF , plywood , particle board , laminated board, composite material ,grass, aluminum and metals . It can give much more excellent performance than HSS .

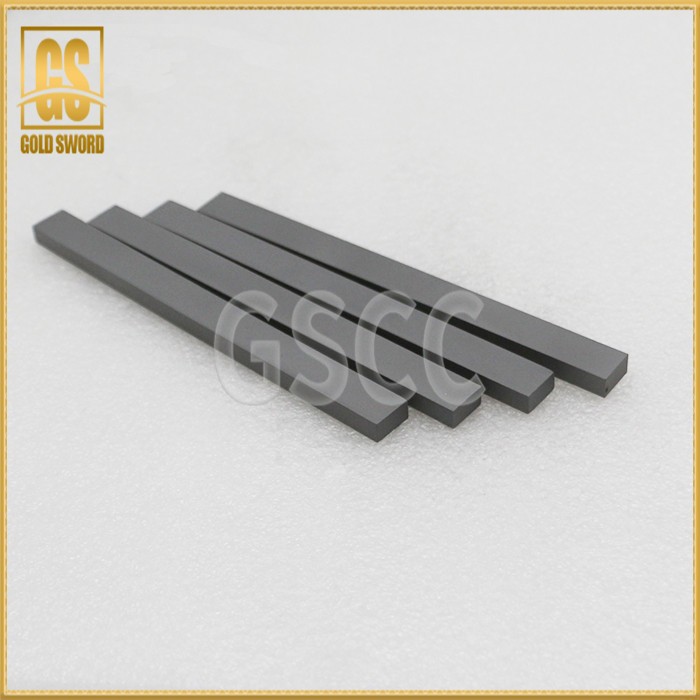

| TICKNESS | WIDTH | LENGTH |

| mm | mm | mm |

| 1~18 | 21 | 50~320 |

| 1~18 | 22 | 50~320 |

| 1~18 | 24 | 50~320 |

| 1~18 | 25 | 50~320 |

| 1~18 | 26 | 50~320 |

| 1~18 | 28 | 50~320 |

| 1~18 | 30 | 50~320 |

| 1~18 | 32 | 50~320 |

| 1~18 | 35 | 50~320 |

| 1~18 | 40 | 50~320 |

| 1~18 | 30 | 50~320 |

| 1~18 | 32 | 50~320 |

| 1~18 | 35 | 50~320 |

| 1~18 | 40 | 50~320 |

| 1~18 | 45 | 50~320 |

| 1~18 | 50 | 50~320 |

| 1~18 | 55 | 50~320 |

| 1~18 | 60 | 50~320 |