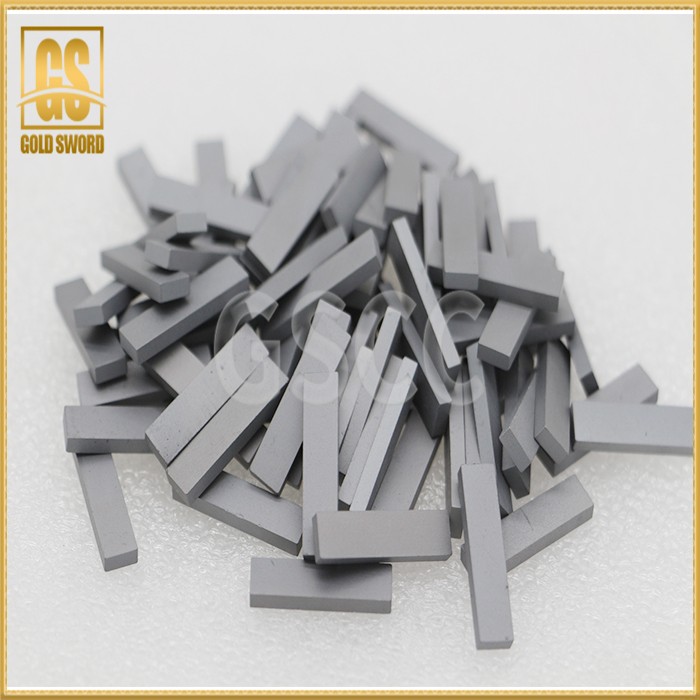

Small films Hard alloy wear resistant parts ,cemented carbide Wear-resistant parts of petroleum equipment

- Home

- >

- Products

- >

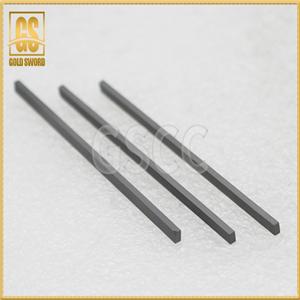

- Carbide Strips

- >

- Small films Hard alloy wear resistant parts ,cemented carbide Wear-resistant parts of petroleum equipment

Small films Hard alloy wear resistant parts ,cemented carbide Wear-resistant parts of petroleum equipment

Brand :gold sword

Product origin :Zhuzhuo

Delivery time :30 days

Supply capacity :30000pcs/month

Our company has served in the petroleum industry for many years, serving the TC bearing manufacturer of petroleum machinery with a relatively large consumption in China, and has a good understanding of the cemented carbide wear parts for centralizers, bearings and window milling cones for petroleum machinery, including their use. The performance and requirements are well understood, and its service life and stability are constantly updated.

We select raw material which is exclusive manufacturer.We make sure we have enough stock,all sizes of strips and types are complete,To ensure the capacity have a monthly output of 5 tons.The company uses advanced testing equipment to continuously formulate and improve the quality control system.

Zhuzhou Gold Sword Cemented Carbide Co., Ltd. Located In Zhuzhou City, Hunan Province, Which Is The Largest Cemented Carbide Production And Sales Base In China. Our Main Products Are Carbide Strips, Carbide STB Bars, Carbide Sand Breaking Strips, Carbide ASA Brazing Tips, Carbide Cold Heading Dies And Carbide Rods. Our Professional And Technical Personnel All Have Above 15 Years Of Cemented Carbide Production Experience, The Rich Experience Can Provide Our Customers Of High-Quality Products And Thoughtful Technical Support, And Continuous Improvement To Meet Customer Needs.

The "stability" and "consistency" of products are the focus of our quality control。

First of all, we have advanced equipment, such as spray tower, Solid furnace , isostatic static pressure punching machine.

Strictly train a quality control technician with outstanding skills,

According to the raw material monitoring, process production and final inspection,

The whole process is strictly monitored in accordance with international quality control system standards;

All-round inspection of products from chemical composition, organization structure, physical properties, appearance size, etc.

Adopt dedicated full-time responsibility system to achieve professional services,when we find problems timely feedback, prompt delivery and solve processing problems quickly.

We have been rooted in the cemented carbide industry and have served foreign trade companies in the Zhuzhou industry for many years. Our customers are mainly metal processing, woodworking and textile tools, petroleum machinery, etc., and are well received by customers.

Based on the damands of customers , for different industries, different materials and different working conditions, provide customers with accurate service and solutions of products, and provide high cost-effective products, to keep the promises of our customers, and Timely provide the professional technical services.

GSGrade | ISO Grade | Density (g/cm3) | Hardness (HRA) | T.R.S (MPα) | Grain Size | Performance & Application Recommended |

RX10 | K20 | 14.6-15.0 | 90~90.5 | 2200~2400 | Medium | High hardness, suitable for roughing of iron, solid wood, dry wood or nonferrous metal, ceramic and other alloys. |

RX20 | K30 | 14.6-15.0 | 90~90.5 | 2600~2800 | Fine | It has high hardness, good toughness and good overall performance. It is suitable for processing all kinds of solid wood, mahogany, medium density board, non-ferrous metal, gray cast iron, etc. |

RX10T | K10 | 14.6-15.0 | 92.5~93 | 1800-2000 | Ultrafine | High hardness, suitable for finishing of iron, nonferrous metal, ceramic and other alloying, semifinishing of of hardwood, chipboard, MDF and HDF. Better to use silver soldering. |

AB10 | K40 | 13.8-14.2 | 87.5~88 | 2800~3000 | Coarse | High toughness, difficult to break tooth. Special used for finger jointing tool. |

YN15 | K40 | 14-14.2 | 85-86 | 1700-1900 | Medium | Mainly used for stamping moulds and ceramic die of electronic components, petroleum machinery corrosion resistant instrument, without magnetic.

|

SK40S | K10 | 14.5 | 91 | 3000-3200 | Fine | High On the basis of ensuring high bending strength, the wear resistance of the alloy is improved, the cutting edge is dense and sharp, which is conducive to the flatness of processing, and has good welding performance. It is used for food package, printing, aluminum foil, metalized film, and gardens. , Textile, leather, plastic, rubber and other mechanical blades. |