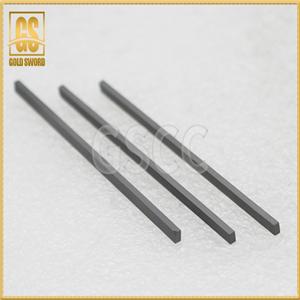

carbide Sand Breaking Strips bar For stone breaker

- Home

- >

- Products

- >

- Carbide Sand Breaking Strips

- >

- carbide Sand Breaking Strips bar For stone breaker

carbide Sand Breaking Strips bar For stone breaker

Brand :Gold Sword

Product origin :Zhuzhou, China

Delivery time :25days

Supply capacity :10000kgs

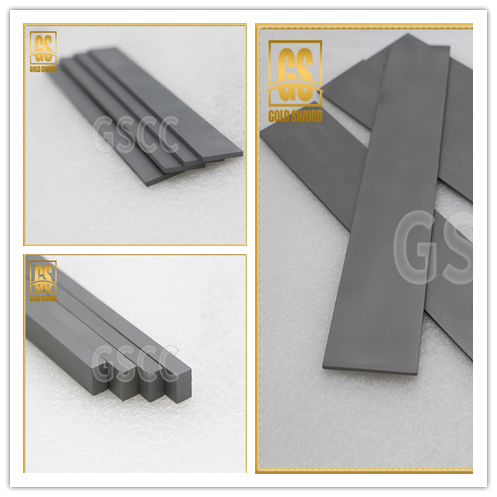

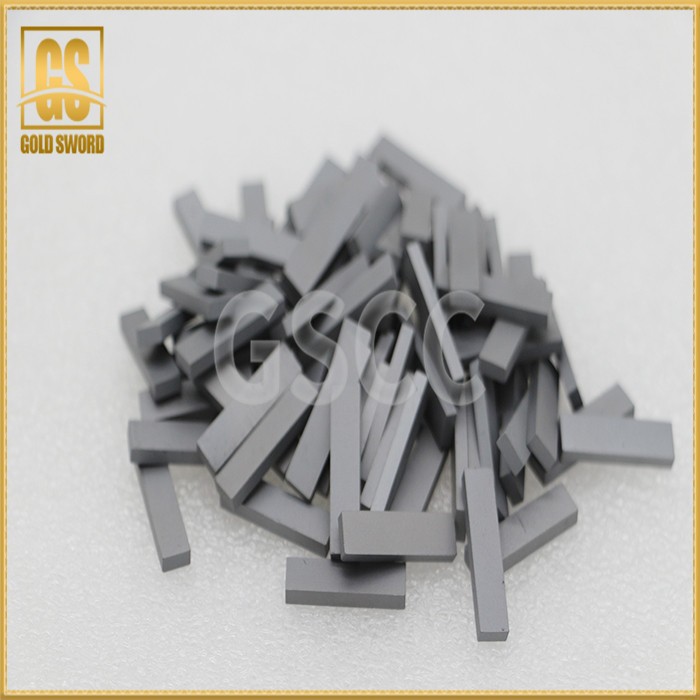

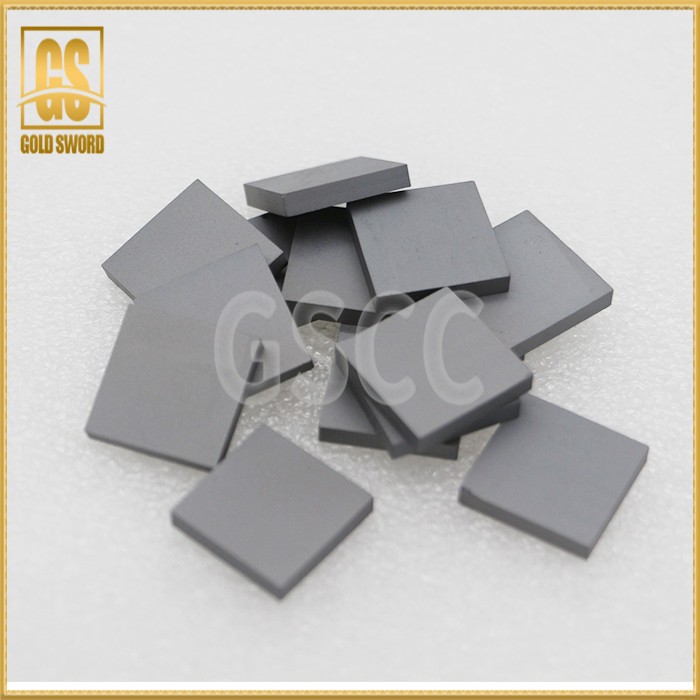

carbide Sand Breaking Strips bar For stone breaker has high hardness and high wear resistance, it is a ideal choice to used in cutting kinds of various stones.

With high quality raw material and advanced equipment, G.S.carbide provides customerGood quality carbide Sand Breaking Strips bar For stone breaker

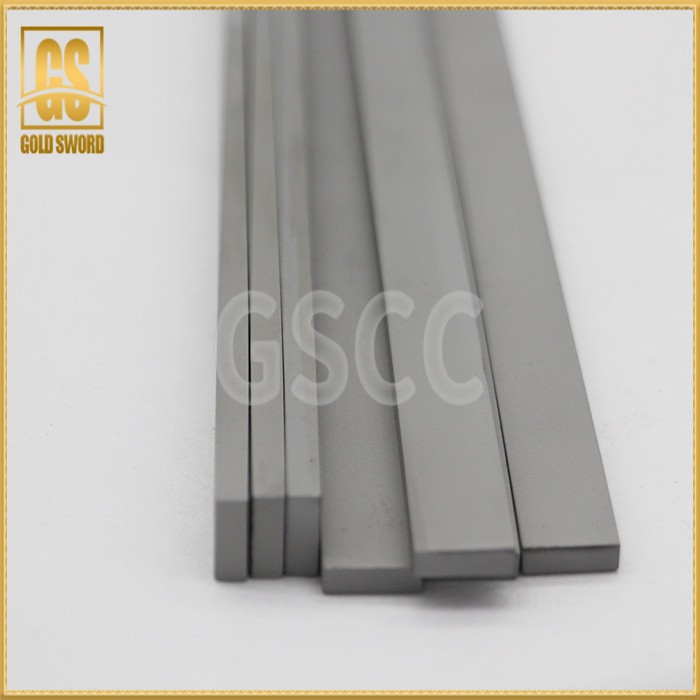

1.Easy to be brazed, good wear resistance and toughness.

2.Untrafine grain size raw material to keep excellent strength and hardness.

3.Both standard sizes and customizes sizes are available.

Tungsten Cemented Carbide Strip for Cutting

Product Description:

carbide Sand Breaking Strips bar For stone breaker is very good has high hardness and high wear resistance, it is a ideal choice to used in cutting kinds of various stones.

With high quality raw material and advanced equipment, G.S.carbide provides customer carbide Sand Breaking Strips bar For stone breaker

1.Easy to be brazed, good wear resistance and toughness.

2.Untrafine grain size raw material to keep excellent strength and hardness.

3.Both standard sizes and customizes sizes are available.

About carbide Sand Breaking Strips bar For stone breaker :

The main composition of tungsten carbide bars or strips is tungsten carbide powders and cobalt powders .With its wear resistant and corrosion resistant ability , tungsten carbide nowadays is widely used in many areas such as : cutting tools , moulds , oil and automobile industry etc .

Tungsten carbide strip and bars is used as the cutter for the TCT woodworking knives for cutting all kinds of original wood , hard wood , HDF, MDF , plywood , particle board , laminated board, composite material ,grass, aluminum and metals . It can give much more excellent performance than HSS .

GSGrade | ISO Grade | Density (g/cm3) | Hardness (HRA) | T.R.S (MPα) | Grain Size | Performance & Application Recommended |

RX10 | K20 | 14.6-15.0 | 90~90.5 | 2200~2400 | Medium | High hardness, suitable for roughing of iron, solid wood, dry wood or nonferrous metal, ceramic and other alloys. |

RX20 | K30 | 14.6-15.0 | 90~90.5 | 2600~2800 | Fine | High toughness, easy to be brazed without heat preservation. Suitable for rosewood, solid wood, pinewood, and other wood with a lot stammer. |

RX10T | K10 | 14.6-15.0 | 92.5~93 | 1800-2000 | Ultrafine | High hardness, suitable for finishing of iron, nonferrous metal, ceramic and other alloying, semifinishing of of hardwood, chipboard, MDF and HDF. Better to use silver soldering. |

AB10 | K40 | 13.8-14.2 | 87.5~88 | 2800~3000 | Coarse | High toughness, difficult to break tooth. Special used for finger jointing tool. |

size

TICKNESS | WIDTH | LENGTH |

mm | mm | mm |

1~10 | 10 | 50~320 |

1~11 | 11 | 50~320 |

1~12 | 12 | 50~320 |

1~13 | 13 | 50~320 |

1~14 | 14 | 50~320 |

1~15 | 15 | 50~320 |

1~16 | 16 | 50~320 |

1~17 | 17 | 50~320 |

1~18 | 18 | 50~320 |

1~18 | 19 | 50~320 |

1~18 | 20 | 50~320 |