News

- Home

- >

- News

- >

- Industry News

- >

- Carbide round bar material performance characteristics

Carbide round bar material performance characteristics

Carbide round bar material performance characteristics

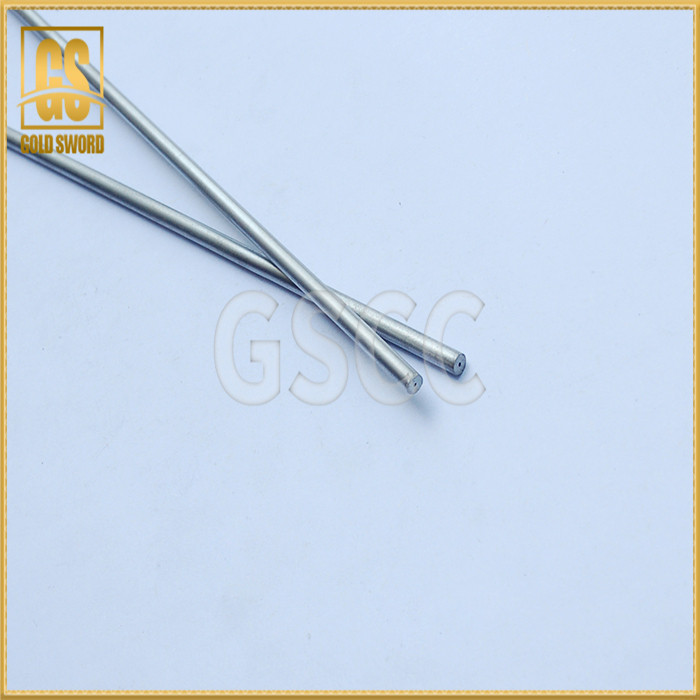

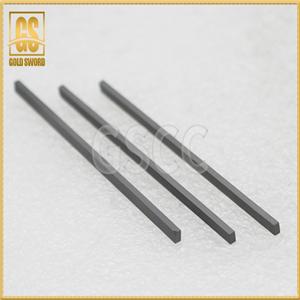

Carbide round bar, also known as cemented carbide bar, is a kind of hard alloy (WC) as the main raw material, plus other precious metals and paste phase by powder metallurgy method for pressing and sintering. Intensive alloy materials are widely used in the field of national production and processing, such as tungsten steel drill bits.

Cemented carbide round bar production process

Milling→Recipe according to the application requirements→wet grinding→mixing→grinding→drying→sieving→post-forming agent→re-drying→sieving to make mixture→granulation→pressing→forming→low-pressure sintering→forming (blank) ) → external grinding grinding (the blank does not have this process) → inspection size → packaging → storage.

Carbide round bar material performance characteristics

1. High-quality ultra-fine tungsten carbide and imported cobalt powder are used as raw materials.

2, using the world's advanced low-pressure sintering preparation technology for standardized production.

3. It has high strength and high hardness.

4, has excellent red hardness, good wear resistance, high modulus of elasticity, high bending strength, good chemical stability (acid, alkali, high temperature oxidation), good impact toughness, low expansion coefficient, thermal conductivity, electrical conductivity and Similar characteristics of iron and its alloys.

5, high-tech precision advanced equipment: Germany imported 10MPa low-pressure sintering furnace sintering.

6, a unique new process: vacuum high temperature and high pressure sintering. The product is pressure sintered in the final stage, which greatly reduces the porosity, improves the compactness, and greatly improves the mechanical properties of the product.

7, product features: material grades, can be applied to different needs of use; complete specifications, accurate blank size (reduced processing, improve production efficiency).

8, the service is thoughtful and quick response: the order is fast, and the delivery is fast and punctual.

Use of carbide rods

Carbide round bar has a wide range of applications, suitable for making tungsten steel drill bits, micro drill bits in the PCB industry, electrode rods in the optoelectronic communication industry, carbide drill bits in the machining industry, drill shanks, top tips, push rods, wear-resistant precision parts, It is the preferred high-quality material for the whole CNC milling cutter and the hole-cutting tool.

carbide bars,carbide strips,Tungsten Carbide Bars,carbide bars blank