News

- Home

- >

- News

- >

- Industry News

- >

- What is a carbide strip?

What is a carbide strip?

What is a carbide strip?

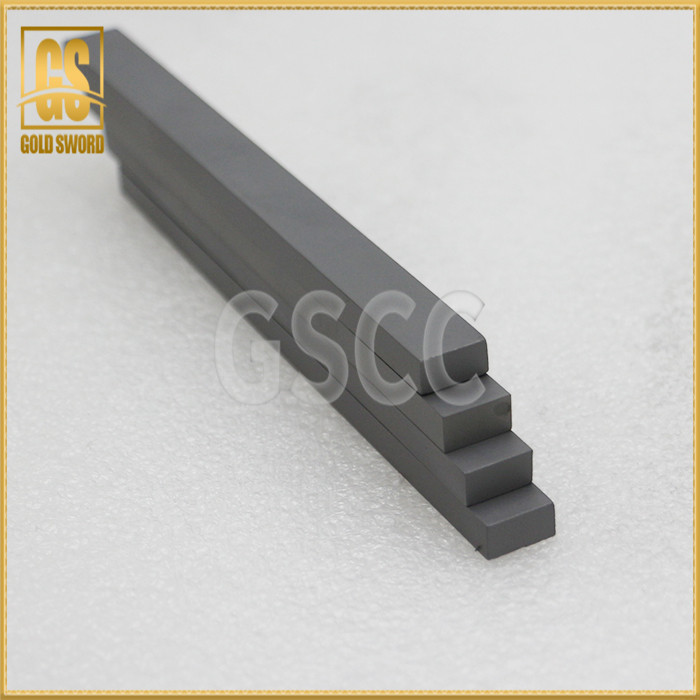

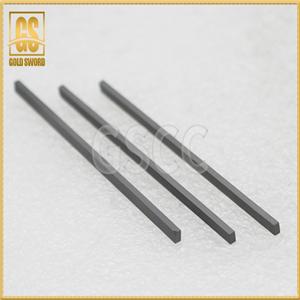

One of the many materials of cemented carbide strips, named for its rectangular shape (or square), also known as the hard alloy strip. Carbide strips are mainly made of WC tungsten carbide and Co-cobalt powder by metallurgy, powder milling, ball milling, pressing and sintering. The main alloy components are WC and Co. WC in hard alloy strips for different purposes. The composition of Co is not consistent with the content of Co, and it is widely used.

Carbide strips have excellent hardness, high hardness, good wear resistance, high modulus of elasticity, high compressive strength, good chemical stability (acid, alkali, high temperature oxidation), low impact toughness, expansion coefficient Low, thermal conductivity, electrical conductivity and iron and its alloys are similar.

The hard alloy strip has the characteristics of high hardness, good weldability, high hardness and high wear resistance. It is mainly used in the production of solid wood, MDF, gray cast iron, non-ferrous materials, chilled cast iron, hardened steel, PCB. Brake material. When using, select the appropriate material of the hard alloy strip according to the purpose.

The performance of several grades of carbide rods:

YT5 has the best strength, impact resistance and shock resistance in tungsten-cobalt-titanium alloy, but its wear resistance is poor. Suitable for roughing and semi-finishing of rough steel for intermittent cutting of carbon steel and alloy steel (including forgings, stampings, cast iron skins).

YT14 has high strength, good impact resistance and shock resistance, and is close to YT5 alloy, but its wear resistance is better than YT5. It is suitable for rough rough milling of carbon steel and alloy steel during continuous cutting, and semi-finishing when intermittent cutting. And fine cars.

YG3X has the best wear resistance in tungsten-cobalt-titanium alloy, but its impact toughness is poor. It is suitable for high-speed finishing of cast iron non-ferrous metals and their alloys, broken fire steel and alloy steel small cut surfaces.

YG6 has higher wear resistance, but lower than YG3, and the impact resistance and vibration are better than YG3X. Suitable for semi-finishing and finishing of medium cutting speeds of cast iron, non-ferrous metals and alloys, non-metallic materials.

YG8 has high strength, impact resistance and shock resistance better than YG6, but wear resistance and allowable cutting speed are lower. Suitable for cast iron, non-ferrous metals and alloys, non-metallic materials for low speed roughing.

YD201 is suitable for semi-finishing and rough machining of cast iron and light alloys, and can also be used for milling of cast iron and low alloy steel.

YW1 has good red hardness and can withstand a certain impact load. It is a versatile alloy. It is suitable for the processing of difficult-to-machine steel such as heat-resistant steel high-manganese steel stainless steel, and is also suitable for the processing of ordinary steel and cast iron.